CALL US TODAY · +31(0)40 2070199

Back to all Branches Solutions

SMALL CHOCOLATE, BARS AND TABLETS

Slide title

Automation product handling small chocolate, bars and tablets

Button

Slide title

Automation product handling small chocolate, bars and tablets

Button

Slide title

Automation product handling small chocolate, bars and tablets

Button

Slide title

Automation product handling small chocolate, bars and tablets

Button

Slide title

Automation product handling small chocolate, bars and tablets

Button

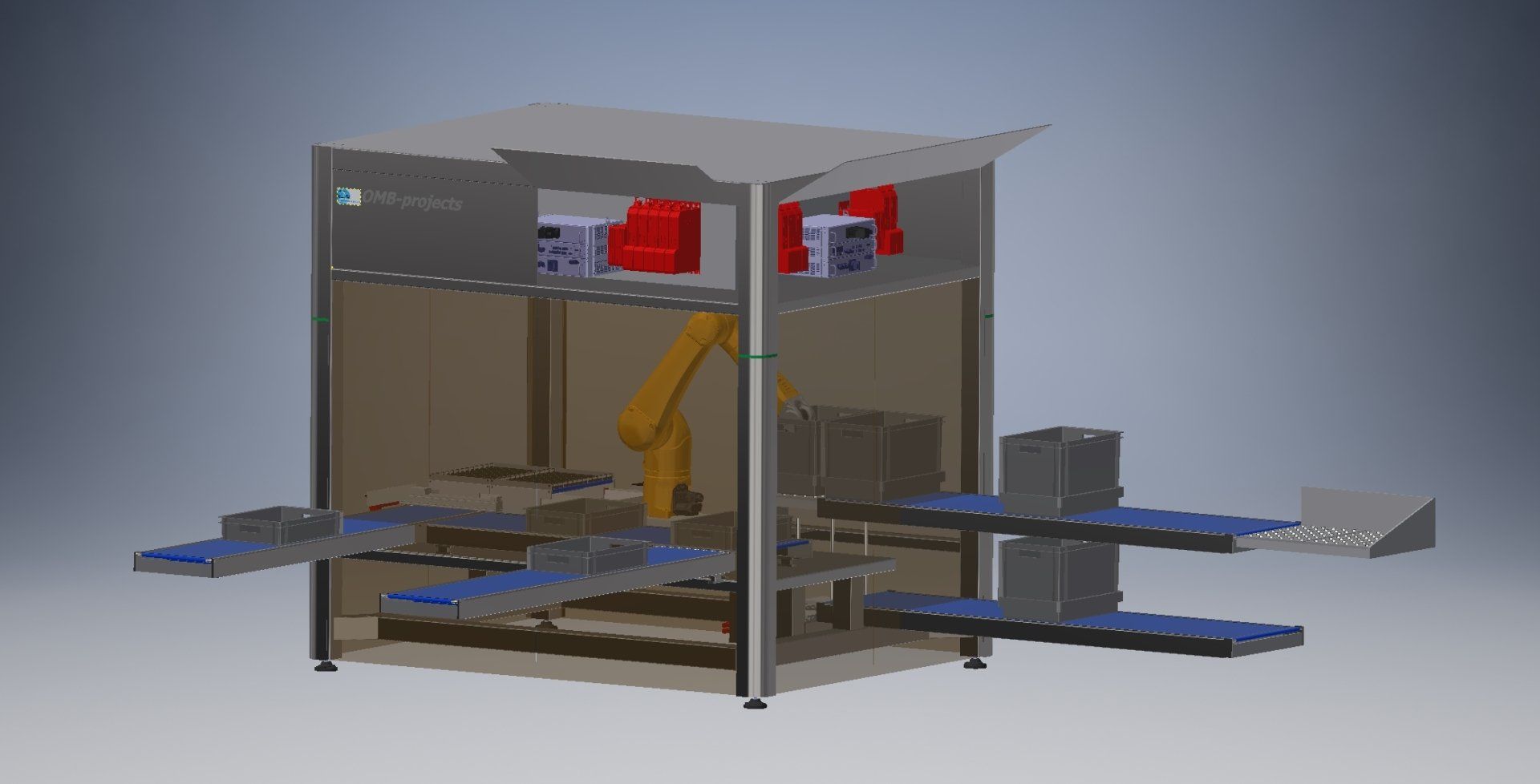

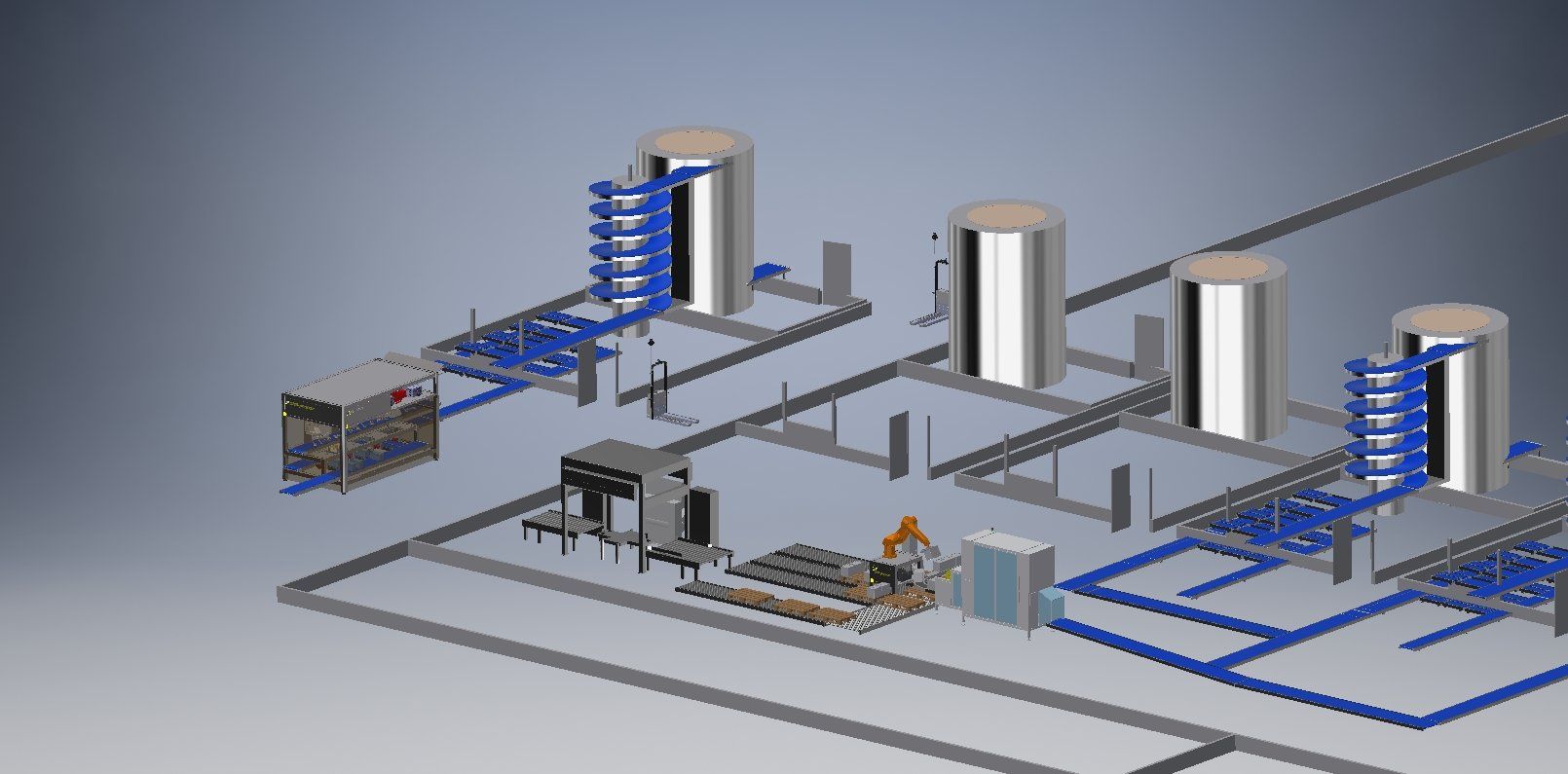

"Stacker & feeder" & "de-stacker" machine solution & display/tray packaging

Chocolate handling automation

Effective

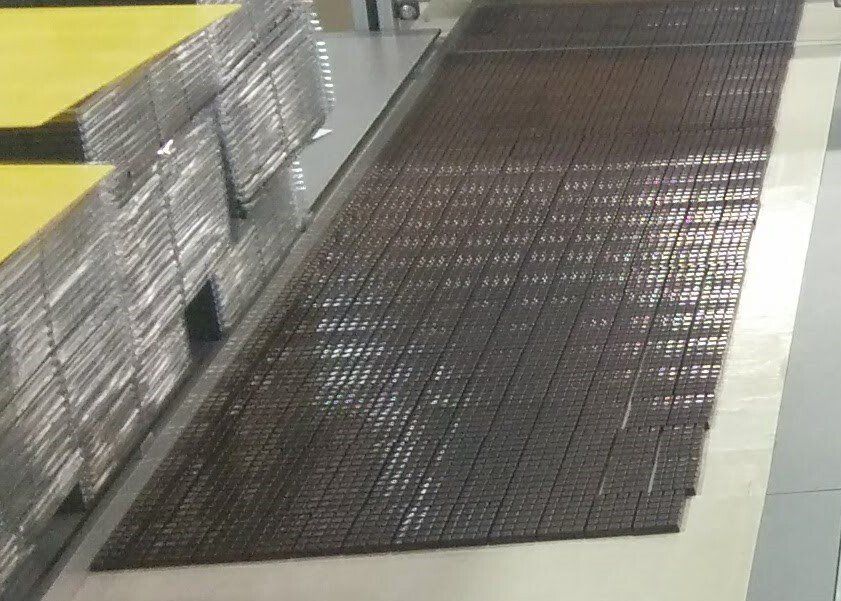

Product handling of small chocolate bars, pick them up directly from the chocolate production molding line and feed them to one or more packaging machines, and “stack” the excess capacity of the molding line for later “destacking” and transferring to the packaging machine(s)

Efficient

The chocolate products are positioned, oriented and controlled with a vision system:

- Napolitains of 4 grams or more, with a processing speed of 1200 Napolitains / min. are possible.

- Bars/tablets handling 75 gr - 500 gr or more, with the processing speed of 400/min. are possible.

Secondary packaging, display / tray or blister

Complete processing of the chocolate products from the molding line and/or from the packing machines or intermediate storage, in order to process them up to speed in display/tray or blister. The display/tray is folded and formed from a blank magazine, and the blister is taken out from the blister magazine.

The chocolate products include;

- Primary packed bars/tablets that are processed with the OMB product handling machine in secondary display/tray packaging with a processing speed of 450 tablets/min. is possible. Depending on a higher feed rate, this is modularly expanded.

PRALINE/BONBON

Slide title

Automation product handling praline/bonbon

Button

Slide title

Automation product handling praline/bonbon

Button

Slide title

Automation product handling praline/bonbon

Button

Slide title

Automation product handling praline/bonbon

Button

Slide title

Write your caption hereButton

"Praline/bonbon" blister & boxes machine solution

Chocolate handling automation

Effective

Product handling of (un)packaged praline/bonbon in all shapes and sizes directly from production molding line with vision system processed in:

- consumer end-blister

- and/or processed in stock- blister/box and/or on plastic plate. Plastic plate placed in the plastic box.

Product handling of (un)packaged praline/bonbon from the plastic plates or from stock blister, in all shapes and sizes, with different variations, in the;

- consumer end-blister

Efficient

OMB praline handling automated directly from the molding line;

- Praline handling in end-blister, modular construction, nominal speed from 350praline/min directly in consumer end-blister.

- Praline handling in stock blister, modular construction, nominal speed from 350praline/min directly in stock blister for later processing, and/or stock blister to chocolaterie retail chain.

- Praline handling on plastic stock plate, nominal speed from 350praline/min and/or with the addition of an automation system in the process, to stack the stock plates with praline in plastic box, for later processing in end-blister.

- Praline handling in storage cardboard box, flexible product handling system for processing praline in box with 350-1600 praline/min. Storage cardboard box ready for transport to chocolaterie store chain.

OMB praline handling, automated from; plastic-plate and/or from stock-blister => to consumer end blister;

- Praline handling to final consumer end-blister with different kinds of praline, modularly constructed with a variation of 1-18 different kinds of pralines, with nominal speed 750 pralines/min possible.

BANQUET & BAKERY

Slide title

Automation product handling banquet & bakery

Button

Slide title

Automation product handling banquet & bakery

Button

Slide title

Automation product handling banquet & bakery

Button

Banquet & bakery automation; cake

Cake handling automation

Effective

Product handling automation cake in blister. Product handling cake with paper cup, placed in blister pack. Placing paper cups, from cup magazine, into baking molds, and placing film-wrapped cake (flowwrapped) in outer carton.

Efficient

The cake and paper cup products are positioned, oriented and controlled with a vision system;

- Cake handling in blister.

- Paper cup handling, placing 2000cups/hour in baking moulds.

- Placing primary packaged cake with product handling in an outer box, in combination with a box erector.

SNACKS (MEAT, VEGA, VEGAN)

Slide title

Automation product handling snacks (meat, vega & vegan)

Button

Slide title

Automation product handling snacks (meat, vega & vegan)

Button

Slide title

Automation product handling snacks (meat, vega & vegan)

Button

Slide title

Automation product handling snacks (meat, vega & vegan)

Button

Slide title

Automation product handling snacks (meat, vega & vegan)

Button

Slide title

Automation product handling snacks (meat, vega & vegan)

Button

Snacks (meat, vega, vegan) automation

Snacks handling automation

Effective

Product handling of snacks, starts immediately after freezing to check for quality, quantity and weight, for further processing in bulk cardboard box with plastic inner bag, or in consumer packaging.

Efficient

The snack products are checked with a vision system, the batches are formed in adjustable quantity, for bulk packaging, with a modular expandable system.

Snacks in end consumer packaging:

- Product handling Snacks burgers 100-200 grams or more, with a processing speed of 300/min. stacking in packaging is possible.

- Product handling Snacks frikandels / croquettes / sausages 70-100 grams or more, place in a package with 400/min. is possible.

With product handling, placing the final consumer packaging in an outer box in combination with an existing cardboard erector.

The outer cardboard boxes scanned, checked and placed on a pallet. Pallet provided with stretch film and transported to warehouse with AGV.

FOOD IN GENERAL

Slide title

Automation food product handling in general

Button

Slide title

Automation food product handling in general

Button

Slide title

Automation food product handling in general

Button

Slide title

Automation food product handling in general

Button

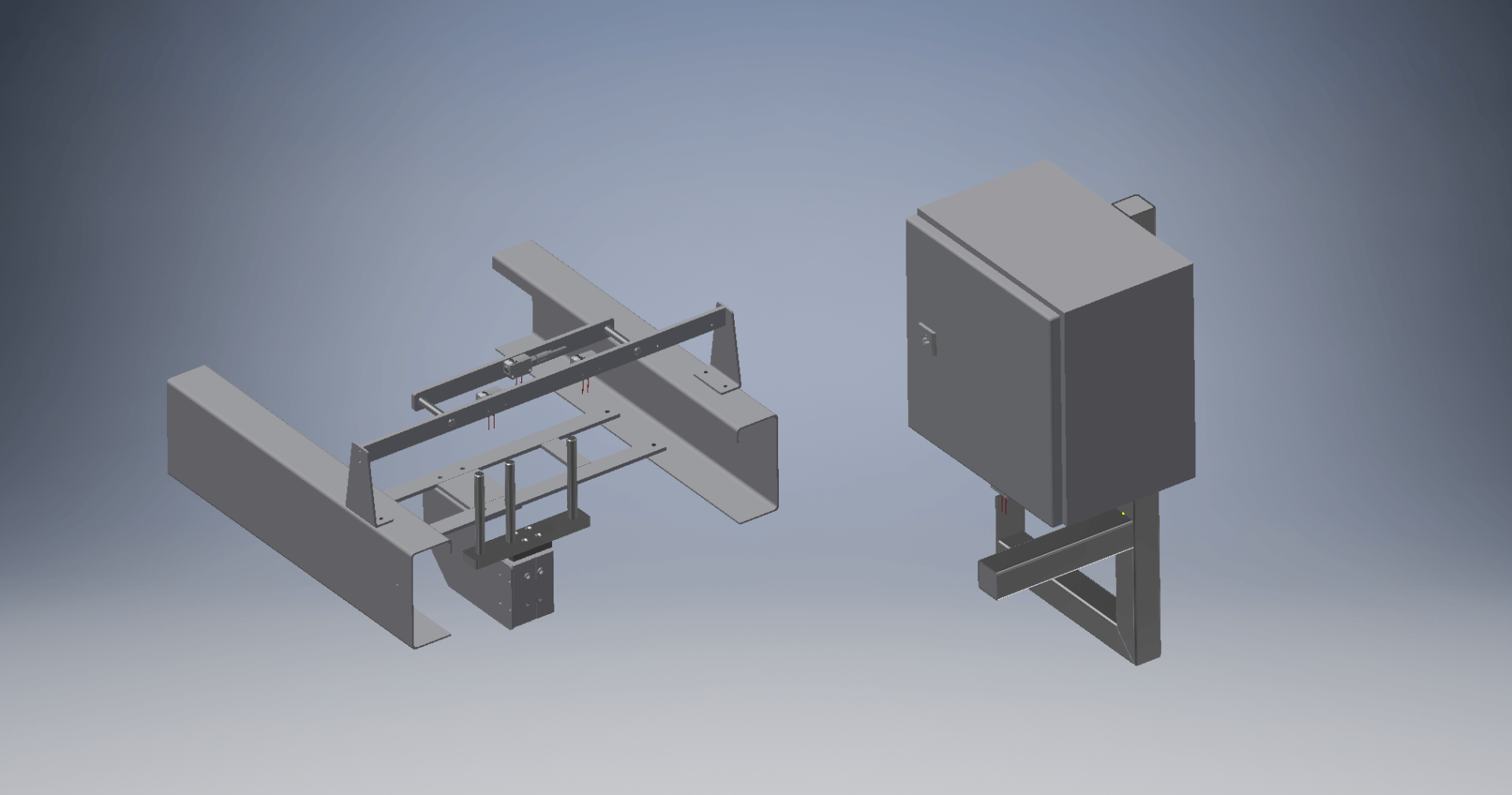

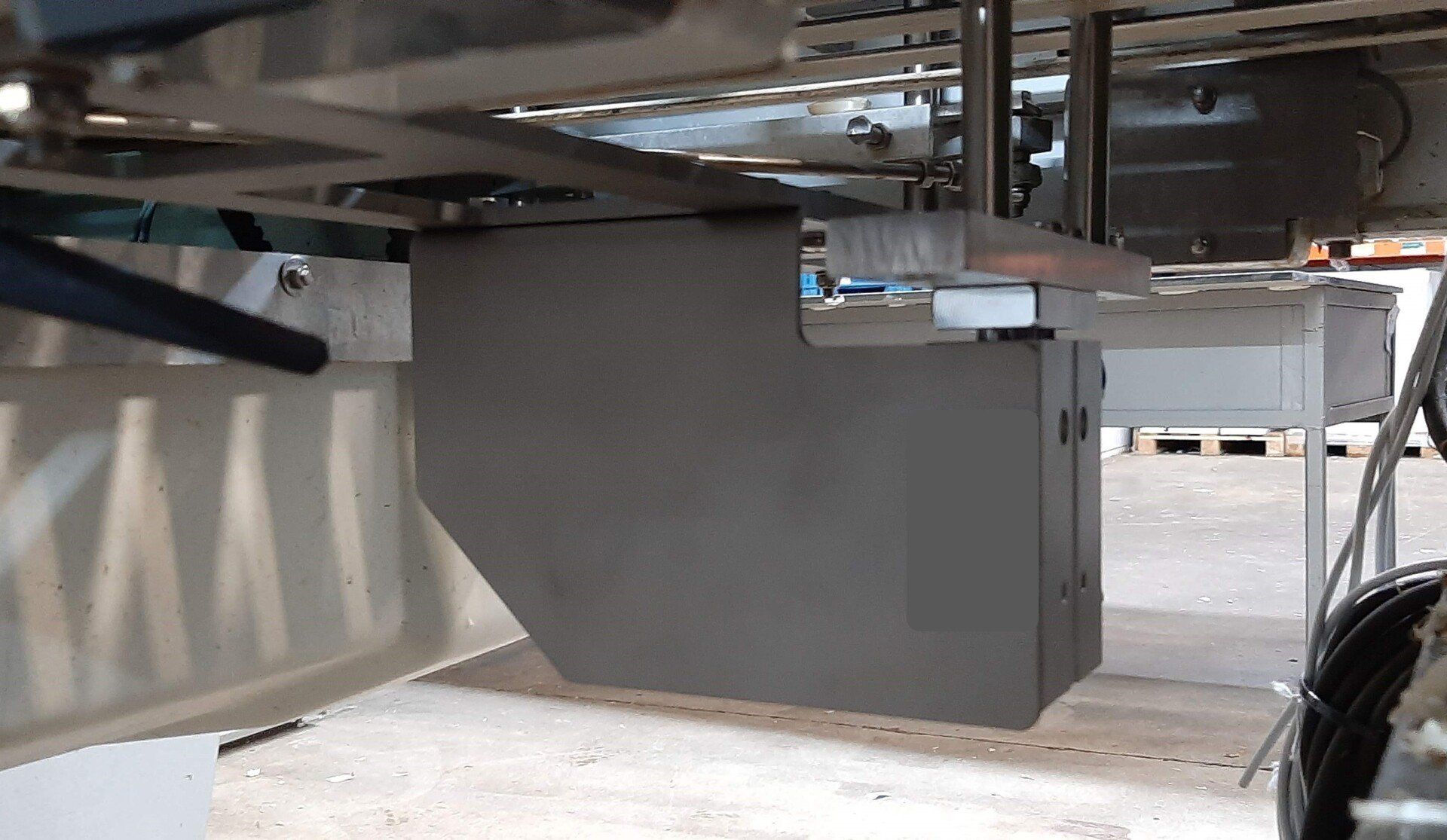

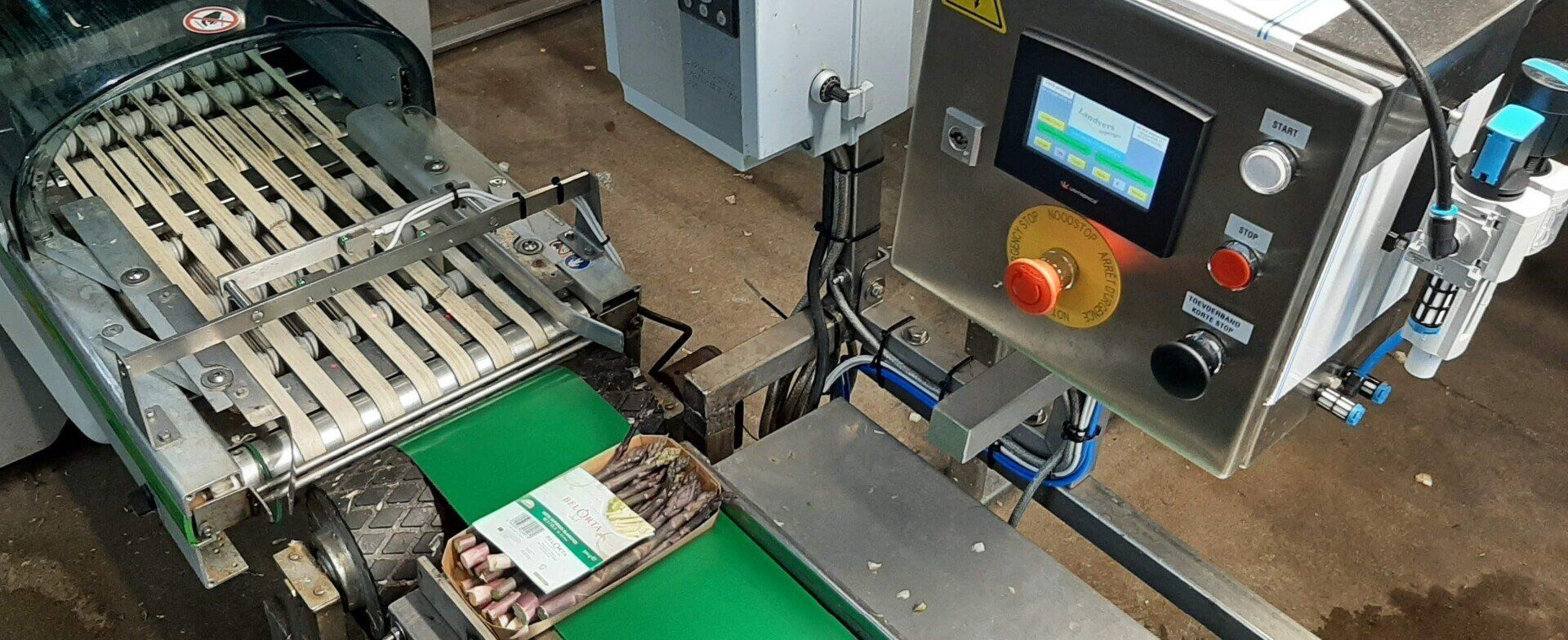

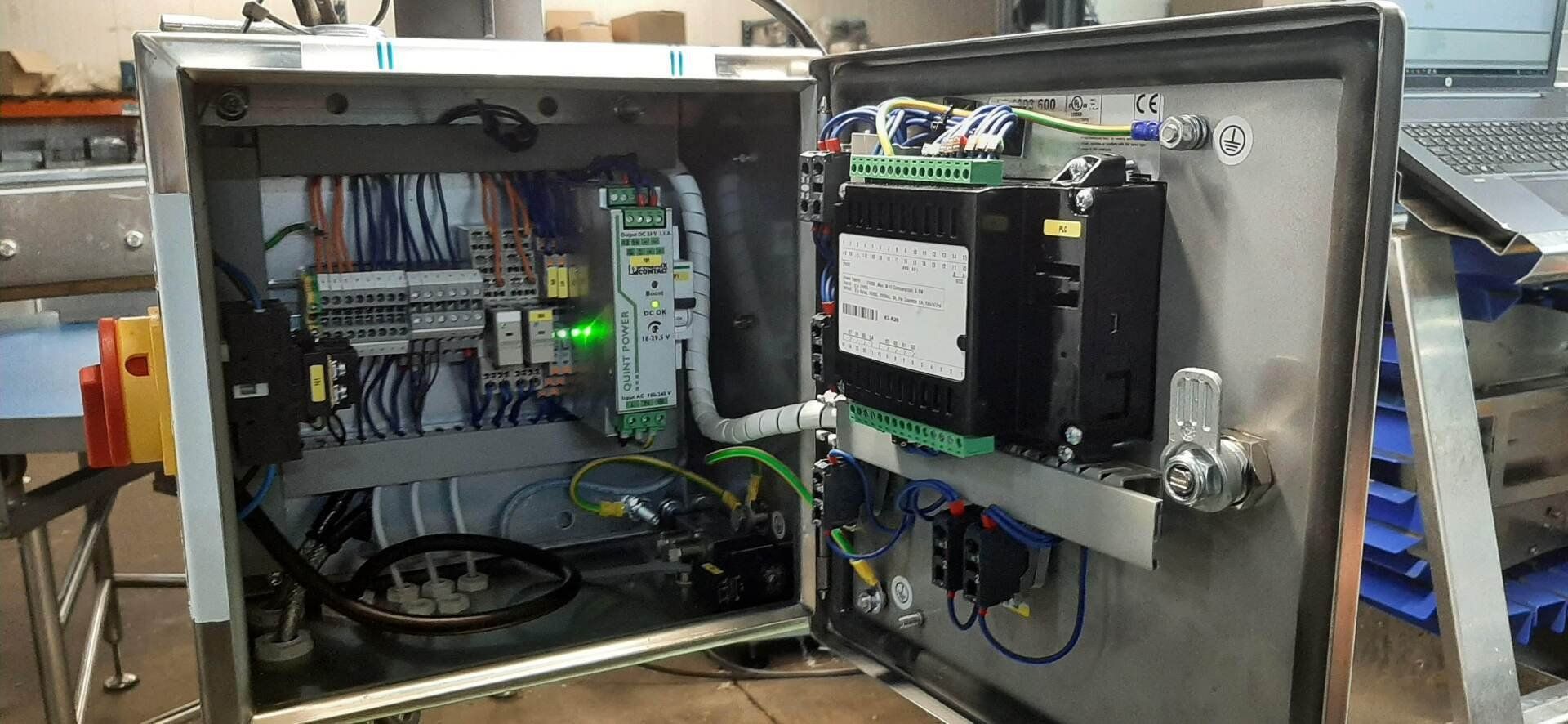

Food in general automation / optimization

Asperge optimization

Effective

Product handling asparagus optimization for straight infeed of asparagus trays, to foil packaging machine.

Efficient

Straighten the variable supply of asparagus trays, to prevent malfunctions in the film packaging machine.