Food Industry

Product -handling -automation & -

optimization

OMB-projects

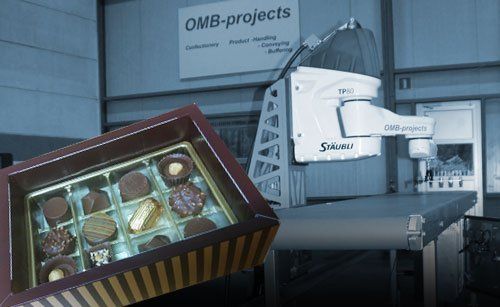

OMB PROJECTS - FOOD / CONFECTIONERY PRODUCT HANDLING

OPTIMIZATION FROM MANUAL PROCESSES TO EFFICIËNT AUTOMATION

WITH A HIGH RETURN ON INVESTMENT

PRODUCT HANDLING CUSTOMER SPECIFIC

In cooperation with =>

thorough process knowledge

After years of experience in the packaging machinery industry, OMB was founded in late 2015 and has specialized in the automation and optimisation of product handling processes, and started in the confectionery industry.

partnerships =>

All levels of automation and independent advice

OMB activities include engineering innovatieve developments, hygienic design, construction and installation.

In coorporation with partnerships in Robotica / electrical components / conveyors / vision application and well-known high quality standard suppliers like; Siemens, Festo, THK, Sick, Pilz, and other, we are very strong in our projects.

we are expert in ;

Delivering customized project solutions

OMB provides automated total solutions with high flexibility for product handling. OMB realizes the automation and optimization of the production processes, with a view to reducing the production cost per product.

OMB-projects

OMB is a company that builds customer-specific machines for the automation of

product handling in the

Food

specialized in the:

confectionery industry

currently further expansion in the branches;

banquet and bakery

&

snacks (meat, vega, vegan)

&

food in general

The "Factory of the Future" is a concept that is increasingly used as a starting point

by companies.

We start with a non-binding analysis of the production process for automation / optimization of producthandling. The automations are carried out with a product quality control through optical 2D/3D Vision, which can also be further implemented with A.I. (Artificial Intelligence). The version with A.I. has the advantage of making the

machine self-steering by means of the registered product deviations

(algorithms), also known as deep learning.

Analysis is done in consultation with the company, then advice and project

proposals, and then elaboration and delivery of the total solutions

with high flexibility of the automated product handling

and the associated product quality control for both;

"small projects" as

"complete line projects"

Expansion from confectionery to => banquet & bakery + snacks + food in general

Product handling

Product handling banquet & bakery products.